We have just returned from Nepal where we visited our small weaving mill in Kathmandu. During our stay we initiated our new designs of handwoven cashmere scarves, which will appear in our webshop as they are finished.

Once in a while we are asked why our cashmere products are so expensive. We don't consider our products to be expensive knowing how much work is put into them, and that's what we will try to focus on here.

Cashmere wool

First of all the price of raw cashmere wool is far more expensive that ordinary wool. At the time of writing, 1 kg of cashmere wool costs about 150 USD. The price is determined by supply and demand. The supply is limited of the fact that cashmere goats only live in high altitude where they develop the fine undercoat in the extreme cold winters. The fine wool makes it possible for the goats to survive the harsh conditions. When the spring arrives and the temperature rises, the goats shed the wool and it is collected by the farmers. Each goat produces about 160 g wool every season.

Cashmere has always been sought after by the major fashion brands in order to deliver the finest quality to their customers. The fine soft wool is beloved and desired around the world, and is considered as the king of wool fibers. The massive demand of this type of wool is making prices soar because the supply is almost constant.

The cashmere wool is sorted in different qualities. The thinner and longer the fiber, the more expensive it is, because the thin long fibers are relatively rare. For our ultra thin shawls we are using the long thin fibers. It ensures a strong yarn despite of the delicate fabric. Our thinnest shawls are so delicate they can be pulled through a finger ring. Hence the name ring shawl.

Our thicker scarves are woven of yarn of shorter fibers that results in a more fluffy yarn. The trick is to find the right quality that fits the purpose.

There is not official classifications of the wool. Some manufacturers are using terms like Grade A and Superior Cashmere, but they are not industrial standards. Therefore we don't use them because it doesn't really make sense. More about myths about cashmere. We are buying our cashmere from vendors we know for a long period of time, and select the quality that fits the purpose based on many years of experience in textile design.

Weaving

The weaving of the scarves is a cumbersome process. Our scarves and shawls from CASHMERE CULTURE are all handwoven. Weaving by hand is a slow process with lots of manual steps that can be broken down in the following workflow:

Dyeing of yarn

If the final textile has a woven pattern, the yarn is dyed before weaving. If it is the final textile is single coloured we dye after the weaving.

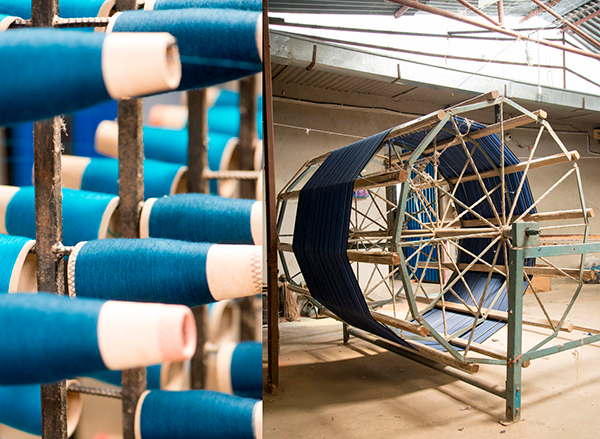

Winding up yarn

When the yarn is dyed and dried, it is wound up on coils. The yarn for the weft, the transverse thread on the loom, is wound up on small coils that fits the shuttle. The shuttle is a hollow device that is pointed in both ends, so it easily glides through the yarn in the lengthwise direction of the loom (the warp). The coil is placed in the cavity of the shuttle. If the textile has multiple colours there will be a shuttle for each colour. It is the weavers task to change colour at the right places, so the pattern will be correct.

The yarn for the warp is first wound up on middlesized coils. Then it is rolled up on a big wheel organized the way the pattern dictates.

Finally the yarn is rolled over to the beam of the loom.

Setting the loom

The beam is moved to the loom where each thread is put through the reed. Again the pattern of the final texttile dicatates which thread is going in which reed. A single error in the setting will affect the entire result.

Weaving

During the weaving, the shuttle is passed back and forth across the loom while the textile is rolled onto the front beam as it is woven. It takes a skilled weaver about 2 hours to weave one shawl. The shawls are woven in one long piece and is cut to shawls when finished.

Quality control and repair

It is unavoidable that small errors occours during the weaving. For the most part they can be fixed after the weaving. If the flaws can't be repaired it is discarded and is used as a sample instead.

Wash and ironing

After quality control the shawls are washed and ironed and are now ready for shipping. By the way, ironing is the only process where we use electricity.

It is a long process with many manual steps. The result is worth the effort. A handwoven cashmere scarf or shawl is a unique accessory which is the outcome of a lot of people making an effort. Whether it is expensive or not is for you to decide. We are certainly proud to deliver a unique product which is not only beautiful and comfortable to wear, it also provides jobs for people in a developing country.